Call:

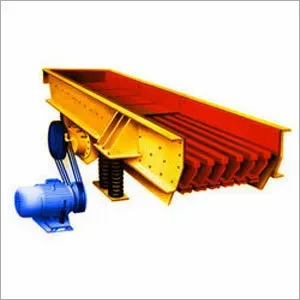

Industrial Vibrating Screen Machine

MOQ : 1-10 Perch

Industrial Vibrating Screen Machine Specification

- Type

- Vibrating Screen Machine

- Material

- Mild Steel / Stainless Steel

- Processing Type

- Automatic

- Condition

- New

- Shape

- Round

- Capacity

- 300-1500 Kg/Hr

- Diameter

- 1000-1800 mm

- Layer

- 1-3 Layers

- Dimension (L*W*H)

- As per model (customizable)

- Power Mode

- Electric

- Voltage

- 220-240 V

- Power Consumption

- 1.5-3 kW

- Media

- Vibration

- Noise Level

- Low

- Frequency

- 50 Hz

- Application

- Industrial Screening, Separation of Materials

- Coating Type

- Powder Coated

Industrial Vibrating Screen Machine Trade Information

- Minimum Order Quantity

- 1-10 Perch

- FOB Port

- Indore

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- Perch

- Delivery Time

- 4-7 Days Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Industrial Vibrating Screen Machine

Buy Online the top-ranking Industrial Vibrating Screen Machine, highlighted for its champion performance and precision. With a mesh size range from 20 to 200 mesh, this remarkable vibrating screen features a power-efficient motor (0.5 HP to 3 HP), customizable discharge outlet, and quick, tool-free screen changeability. The robust design includes direct or indirect drive, low noise, safety covers, emergency stop, and powder-coated finish. Designed for industrial screening, it is suitable for mild steel and stainless steel construction. Markdown prices available from Indias leading manufacturer, supplier, and service provider.

Extensive Usage & Versatile Plant Applications

The Industrial Vibrating Screen Machine is engineered to excel in separating materials for industries such as pharmaceuticals, chemicals, minerals, and food processing. Its automatic operation and customizable screen sizes enable usage across multiple plant applications, including sieving, grading, and de-dusting. With its robust mobility and rapid screen replacement, this champion machine meets the diverse needs of modern, high-capacity plants, making it a remarked solution for continuous industrial processing.

Export Markets, Purchase Rate & Delivery Policy

Our Industrial Vibrating Screen Machine is exported to several global markets owing to its reliability and performance. Sample policies are flexible, intended to facilitate confident purchase decisions. Delivery time varies based on model and order volume, with rates clearly detailed in our purchase order information. Freight charges are transparent and competitive, ensuring timely shipment and safe handling. We prioritize customer satisfaction from inquiry to delivery, supporting all orders with responsive after-sales service.

Extensive Usage & Versatile Plant Applications

The Industrial Vibrating Screen Machine is engineered to excel in separating materials for industries such as pharmaceuticals, chemicals, minerals, and food processing. Its automatic operation and customizable screen sizes enable usage across multiple plant applications, including sieving, grading, and de-dusting. With its robust mobility and rapid screen replacement, this champion machine meets the diverse needs of modern, high-capacity plants, making it a remarked solution for continuous industrial processing.

Export Markets, Purchase Rate & Delivery Policy

Our Industrial Vibrating Screen Machine is exported to several global markets owing to its reliability and performance. Sample policies are flexible, intended to facilitate confident purchase decisions. Delivery time varies based on model and order volume, with rates clearly detailed in our purchase order information. Freight charges are transparent and competitive, ensuring timely shipment and safe handling. We prioritize customer satisfaction from inquiry to delivery, supporting all orders with responsive after-sales service.

FAQs of Industrial Vibrating Screen Machine:

Q: How does the Industrial Vibrating Screen Machine operate?

A: The machine operates using vibratory motion generated by an unbalanced motor. This motion enables efficient separation and screening of material, with direct or indirect drive options for different processing needs.Q: What are the benefits of quick and tool-free screen replacement?

A: Quick and tool-free screen replacement reduces downtime and boosts productivity, allowing operators to swap screens swiftly for different mesh sizes without specialized tools or prolonged interruption.Q: When should I consider adding caster wheels for mobility?

A: Caster wheels are recommended when frequent machine relocation within your plant is required, providing flexibility and ease of movement without manual lifting or auxiliary equipment.Q: Where can I install the vibrating screen machine?

A: This machine is suitable for onsite assembly in a range of industrial settings and requires minimal installation effort. It accommodates diverse dimensions and can be tailored to specific plant layouts.Q: How does the discharge outlet customization benefit my process?

A: Customizable discharge outlets enable seamless integration with existing processing lines, optimizing material flow and streamlining separation according to your plants unique specifications.Q: What applications is this vibrating screen machine best suited for?

A: This machine excels in screening, grading, separation, and de-dusting materials across sectors like pharmaceuticals, chemicals, minerals, food, and more, making it highly versatile for industrial use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Vibrating Screen Machine Category

Industrial Vibrating Feeder Machine

Price Range 200000.00 - 200000.00 INR / Perch

Minimum Order Quantity : 110 Perch

Condition : New

Power Mode : Electric

Shape : Other, Rectangular Hopper

Sand Vibrating Screen Machine

Price 2.65000 INR / Perch

Minimum Order Quantity : 110 Perch

Condition : New

Power Mode : Electric

Shape : Other

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry