Call:

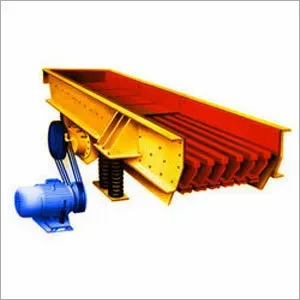

Industrial Vibrating Feeder Machine

MOQ : 1-10 Perch

Industrial Vibrating Feeder Machine Specification

- Type

- Electromagnetic Vibrating Feeder

- Material

- Mild Steel / Stainless Steel

- Processing Type

- Automatic

- Condition

- New

- Shape

- Rectangular Hopper

- Capacity

- 50-500 TPH (Depending on Model)

- Layer

- Single

- Dimension (L*W*H)

- Customized or Standard Size

- Power Mode

- Electric

- Voltage

- 220-240 V

- Power Consumption

- 1.5-5 kW (Depending on Size and Model)

- Media

- Bulk Materials (Granules, Powders, Aggregates)

- Noise Level

- 80 dB

- Frequency

- 50/60 Hz

- Application

- Feeding and Conveying of Materials in Mining, Metallurgy, Construction, Chemical Industries

- Coating Type

- Powder Coated or Painted

Industrial Vibrating Feeder Machine Trade Information

- Minimum Order Quantity

- 1-10 Perch

- FOB Port

- Indore

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- Perch

- Delivery Time

- 4-7 Days Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Industrial Vibrating Feeder Machine

Procure the laureate among industrial feeding solutions our dazzling Industrial Vibrating Feeder Machine. Engineered with valorous precision, each unit features an advanced electronic controller for adjustable feeding speed and a customizable discharge port size to harmonize with your unique applications. Boasting an electromagnetic drive, robust mild steel or stainless steel tray, and low-maintenance, anti-corrosive surfaces, these feeders excel in mining, metallurgy, construction, and chemical industries. Valuation and advance purchase options are available for standard or customized models, ensuring seamless integration and superior productivity.

Industrial Vibrating Feeder Machine: The Dazzling Standard for Industries

Our Industrial Vibrating Feeder Machine offers primary competitive advantages such as adjustable vibration amplitude, electronic control, and customizable discharge port size. Designed for durability and effortless integration, it is best suited for continuous feeding and metering of bulk materials in mining, metallurgy, chemical, and construction domains. Special features include low maintenance requirements, a smooth anti-corrosive finish, and a base-mounted design, making it a valorous choice for demanding industrial environments.

Domestic Market Reach, Valuation, and Delivery of Vibrating Feeder Machines

We service Indias main domestic markets with comprehensive proposals, providing accurate valuation and transparent proposal amounts. Our procurement process ensures reliable transportation of each feeder machine, regardless of size or specification. Standard lead times and delivery schedules are defined during order confirmation, catering to urgent or advance purchase needs. Samples can be arranged upon request, ensuring customer confidence before full-scale procurement or deployment.

Industrial Vibrating Feeder Machine: The Dazzling Standard for Industries

Our Industrial Vibrating Feeder Machine offers primary competitive advantages such as adjustable vibration amplitude, electronic control, and customizable discharge port size. Designed for durability and effortless integration, it is best suited for continuous feeding and metering of bulk materials in mining, metallurgy, chemical, and construction domains. Special features include low maintenance requirements, a smooth anti-corrosive finish, and a base-mounted design, making it a valorous choice for demanding industrial environments.

Domestic Market Reach, Valuation, and Delivery of Vibrating Feeder Machines

We service Indias main domestic markets with comprehensive proposals, providing accurate valuation and transparent proposal amounts. Our procurement process ensures reliable transportation of each feeder machine, regardless of size or specification. Standard lead times and delivery schedules are defined during order confirmation, catering to urgent or advance purchase needs. Samples can be arranged upon request, ensuring customer confidence before full-scale procurement or deployment.

FAQs of Industrial Vibrating Feeder Machine:

Q: How is the vibration amplitude adjusted in the Industrial Vibrating Feeder Machine?

A: The vibration amplitude can be flexibly adjusted between 1 to 7 mm using the electronic controller, enabling precise feeding rates tailored to various material types and process requirements.Q: What customization options are available for discharge port size and dimensions?

A: The discharge port size and overall dimensions of the feeder can be customized to fit your facilitys specific spatial constraints and operational demands, ensuring optimal integration into your systems.Q: When should an advance purchase be considered for this machine?

A: Advance purchase is recommended for clients requiring custom fabrication, large quantities, or integration within time-sensitive projects, to ensure timely delivery and system alignment.Q: Where can the Industrial Vibrating Feeder Machine be effectively utilized?

A: This machine is suitable for applications in mining, construction, metallurgy, and chemical industries, providing robust feeding and metering solutions for bulk materials across various production lines.Q: What are the primary benefits of using an electromagnetic drive in this feeder?

A: The electromagnetic drive provides precise, smooth, and energy-efficient vibration control, resulting in consistent material feed rates, reduced mechanical wear, and ease of maintenance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Vibrating Screen Machine Category

Industrial Vibrating Screen Machine

Price Range 370000.00 - 370000.00 INR / Perch

Minimum Order Quantity : 110 Perch

Shape : Other, Round

Power Mode : Electric

Condition : New

Sand Vibrating Screen Machine

Price 2.65000 INR / Perch

Minimum Order Quantity : 110 Perch

Shape : Other

Power Mode : Electric

Condition : New

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry