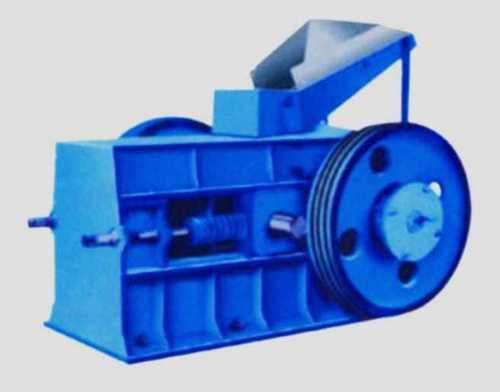

Roll Crusher Machine

MOQ : 1-10 , , Perch

Roll Crusher Machine Specification

- Motor Power

- 5 HP / 7.5 HP / 10 HP (As per model)

- Surface

- Paint Coated

- Product Type

- Roll Crusher Machine

- General Use

- Crushing of minerals, stones, and ores

- Material

- Other

- Type

- Double Roll Crusher

- Capacity

- 2 - 10 TPH (As per size/model)

- Weight (kg)

- Approx. 1200 - 2300 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual/Starter panel

- Cooling System

- Air Cooling

- Method

- Compression & Shear

- Voltage

- 415 V, 3 Phase, 50 Hz

- Dimension (L*W*H)

- 2500 mm x 1200 mm x 1000 mm (approx., varies with model)

- Feature

- High crushing ratio, low noise, easy maintenance

- Color

- Grey/Blue

Roll Crusher Machine Trade Information

- Minimum Order Quantity

- 1-10 , , Perch

- FOB Port

- Indore

- Supply Ability

- 1 , , Perch Per Day

- Delivery Time

- 4-7 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Roll Crusher Machine

Access unrivaled efficiency with our Roll Crusher Machine, engineered for rarefied performance in demanding applications. With adjustable output sizes from 1050 mm and a feeding capacity up to 100 mm, this double roll crusher proves uncommon in versatility. Available in roll diameters of 250600 mm and widths of 3001000 mm, it delivers an impressive 2-10 TPH, powered by 510 HP electric motors. Ideal for mining, aggregates, cement, and chemicals, it offers a high crushing ratio, low noise, and easy maintenancemaking it the in-demand solution for mineral, stone, and ore processing. Computerized features are minimized, ensuring intuitive manual control and straightforward operation.

Roll Crusher Machine: Uncommon Features & Versatile Applications

The Roll Crusher Machine provides outstanding performance, combining a high crushing ratio with low operational noise. Its robust construction ensures durability, while the adjustable output size adapts to various materials, including minerals, stones, and ores. Special paint-coated surfaces shield against wear, and air cooling maintains optimal temperatures. Whether in mining, aggregates, cement, chemicals, or construction, this machine handles diverse application mediaguaranteeing reliable, consistent results for high-demand environments.

Certifications, Delivery, and Packing for Domestic Markets

Our Roll Crusher Machine is supplied with trusted certifications and detailed technical documents to assure quality. Each unit receives meticulous packing and timely dispatch to safeguard equipment during transit. Delivery time varies depending on model selection and proposal amount, with prompt shipments from the designated FOB port in India. Dedicated to the domestic mar, we provide professional assistance throughout the procurement process for seamless installation and commissioning.

Roll Crusher Machine: Uncommon Features & Versatile Applications

The Roll Crusher Machine provides outstanding performance, combining a high crushing ratio with low operational noise. Its robust construction ensures durability, while the adjustable output size adapts to various materials, including minerals, stones, and ores. Special paint-coated surfaces shield against wear, and air cooling maintains optimal temperatures. Whether in mining, aggregates, cement, chemicals, or construction, this machine handles diverse application mediaguaranteeing reliable, consistent results for high-demand environments.

Certifications, Delivery, and Packing for Domestic Markets

Our Roll Crusher Machine is supplied with trusted certifications and detailed technical documents to assure quality. Each unit receives meticulous packing and timely dispatch to safeguard equipment during transit. Delivery time varies depending on model selection and proposal amount, with prompt shipments from the designated FOB port in India. Dedicated to the domestic mar, we provide professional assistance throughout the procurement process for seamless installation and commissioning.

FAQs of Roll Crusher Machine:

Q: How does the Roll Crusher Machine adjust output size for different materials?

A: The Roll Crusher Machine features an adjustable output size mechanism, allowing you to set the discharge range between 10 mm and 50 mm. This adaptability caters to various material requirements and industry applications.Q: What industries can benefit from using this Roll Crusher?

A: Industries such as mining, aggregates, cement, chemicals, and construction all benefit from the Roll Crusher Machines efficient mineral, stone, and ore crushing capabilities.Q: When should I perform maintenance on the Roll Crusher Machine?

A: Regular maintenance, such as checking roller surfaces and lubrication, should be performed according to usage intensity. The design ensures maintenance tasks remain low-effort and infrequent.Q: Where is the Roll Crusher Machine manufactured and supplied from?

A: Our Roll Crusher Machines are manufactured, supplied, and serviced in India, supporting both standard and custom requirements for domestic and export customers.Q: What is the process for ordering and receiving the machine in India?

A: Customers can submit a proposal amount for their selected model. Upon order confirmation, we arrange packing, dispatch, and delivery from the designated FOB port, ensuring secure transit and timely arrival.Q: How does the machines control system operate?

A: The Roll Crusher Machine utilizes a manual/starter panel control system, ensuring straightforward operation without complex computerized components, suitable for semi-automatic handling.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Crusher Machine Category

Jaw Crusher Machine

Price 100000 INR / Perch

Minimum Order Quantity : 1 , , Perch

Material : Other, Mild Steel

Product Type : Jaw Crusher Machine

General Use : Stone Crushing

Voltage : 440 V

Stone Jaw Crusher Machine

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Product Type : Stone Jaw Crusher Machine

General Use : Industrial

Voltage : 220240 Volt (v)

Mobile Impact Crusher Machine

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other

Product Type : Mobile Impact Crusher Machine

General Use : Industrial

Voltage : 220240 Volt (v)

Soil Crushing Machine

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Product Type : Soil Crushing Machine

General Use : Industrial

Voltage : 220240 Volt (v)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry